For electronics and semiconductor manufacturers, contamination control goes beyond dust. Modern cleanrooms—whether in wafer fabs, PCB assembly facilities, optical facilities, or EV battery production lines—require strict management of static electricity and micro-particulates. Even minor ESD events or microscopic lint can damage sensitive components, interrupt production, and create large-scale yield loss.

At AAWipes, we support global semiconductor and electronics facilities with ESD-safe wipes, low-lint polyester wipes, ultra-fine microfiber wipes, and cleanroom swabs—all backed by U.S. quality control from our Michigan team, fast fulfillment from our U.S. warehouse, and free global shipping.

Why Static Control Is Mission-Critical in Semiconductor & Electronics Cleanrooms

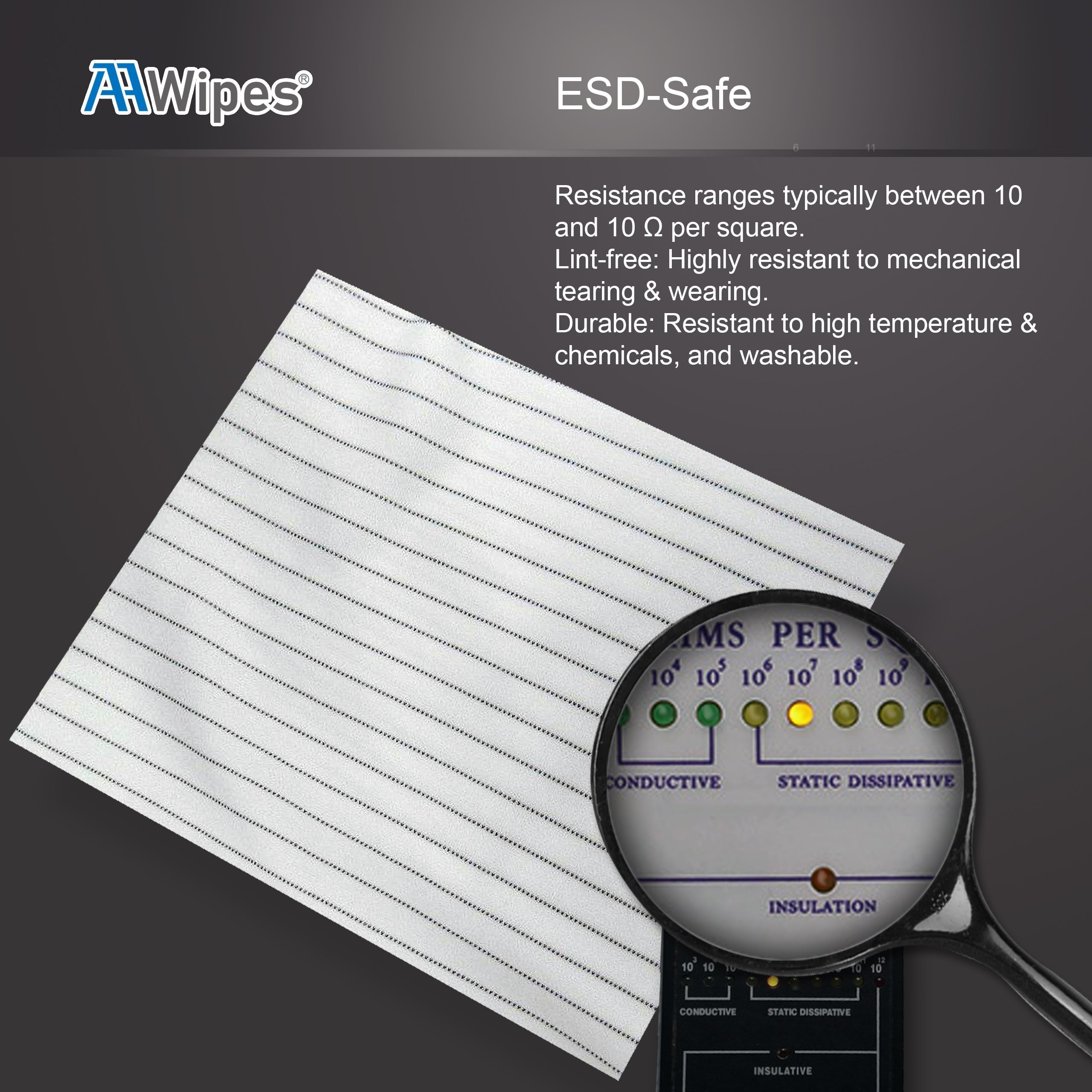

Electrostatic discharge (ESD) can silently damage IC chips, sensors, printed circuits, optical components, and micro-electronics. In Europe and North America—especially in high-value fabs—manufacturers require cleaning materials that maintain:

-

Consistent surface resistivity

-

Low triboelectric charge generation

-

Minimal particle shedding

-

Chemical resistance for IPA and solvent use

-

Lint-free performance for ISO Class cleanrooms

AAWipes’ ESD-safe polyester wipes, ESD swabs, and microfiber wipes are engineered to reduce static generation while providing superior particulate control.

Low-Lint Cleaning in High-Sensitivity Environments

Modern semiconductor fabs in Germany, the Netherlands, Italy, the U.S., and Canada demand cleaning tools that leave zero residue and zero lint.

Our cleanroom wipes provide:

✔ Low particle release

Ideal for wafer handling, sensor assembly, medical electronics, and optical component cleaning.

✔ High absorbency

Compatible with IPA, acetone alternatives, HE-15, and audit-approved solvents.

✔ Uniform sealed edges

Laser-sealed or ultrasonic-sealed to prevent fiber shedding.

✔ Stable consistency

All lots are QC-verified in Michigan before leaving our warehouse.

Supply Chain Reliability for European & North American Fabs

Semiconductor OEMs and Tier-1 facilities increasingly prioritize supply chain stability, especially for consumables such as cleanroom wipes, sticky mats, and swabs.

AAWipes ensures:

U.S. Quality Control (Michigan Team)

Every batch is inspected, tested, and verified before release.

U.S. Warehouse — Fast Dispatch

Most orders ship within 24 hours, reducing downtime risk.

🌍 Free Global Shipping

Including Europe, the UK, Canada, and APAC.

📦 Stable Inventory for Large-Scale Buyers

We maintain buffer stock for enterprise clients to avoid production interruptions.

🔄 Consistent Repeatability

ISO-aligned quality checks ensure batch-to-batch stability—critical for sensitive wafer or optical production.

Case Study: Automotive Electronics Manufacturer in Michigan

A Tier-1 automotive electronics facility in Michigan needed ESD-safe wipes and low-lint microfiber wipes for PCB module cleaning, final inspection, and sensor assembly.

Challenges:

-

Unpredictable supply from previous vendors

-

Static issues affecting inspection yield

-

High lint contamination during assembly

AAWipes Solution:

-

Provided ESD16009 ESD wipes and Class 100 Microfiber Wipes

-

Set up monthly auto-replenishment

-

Delivered all shipments from our U.S. warehouse with same-day fulfillment

Results within 60 days:

-

19% reduction in inspection-related re-cleaning

-

Zero ESD-related cleaning defects reported

-

Improved supply chain reliability and traceability

Recommended Products for Semiconductor & Electronics Facilities

1. ESD-Safe Polyester Wipes (White/Yellow) – 6" x 6"

Perfect for PCB assembly, wafer handling, and sensor modules.

2. Ultra-Fine Microfiber Wipes

Ideal for optics, laser components, camera modules, and lenses.

3. Class 100-1000 Cleanroom Polyester Wipes

High absorbency + near-zero particle generation.

4. ESD-Safe Swabs (multiple head shapes)

Engineered for microscopic cleaning in tight spaces.

5. Cleanroom Sticky Mats (24"x36")

Reduces foot-traffic contamination in ISO-controlled areas.

Why Enterprise Procurement Teams Choose AAWipes

-

Michigan-based QC team ensures strict, consistent quality

-

U.S. warehouse for fast replenishment

-

Free global shipping for EU & North America

-

Competitive pricing for industrial distributors and OEMs

-

92% repeat purchase rate from current clients

-

Trusted by Fortune 500, aerospace, optics, medical device, and electronics manufacturers

Conclusion

For semiconductor fabs, electronics cleanrooms, and high-precision manufacturing environments, selecting the right ESD-safe and low-lint cleaning materials protects production yield and supply chain consistency.

AAWipes supports global customers with U.S.-controlled quality, dependable shipping, and proven cleanroom performance—ensuring your teams can operate with confidence.