In semiconductor fabrication, even a single particle can compromise yield. That’s why leading manufacturers invest heavily in quality control — starting with their choice of cleanroom wipes supplier. The right semiconductor wipes supplier ensures not just surface cleanliness, but also consistent performance, static safety, and delivery reliability.

Here are the three most important factors semiconductor buyers consider when selecting a wipes supplier — and how AAWipes delivers measurable value in each area.

1. Cleanroom Classification: From Class 100 to Class 1000

Every cleanroom environment has a specific contamination threshold. Semiconductor fabs typically operate between Class 100 to Class 1000, where airborne particles must be tightly controlled.

AAWipes offers a complete line of Class 100–1000 cleanroom wipes, available in 100% polyester and cellulose-polyester blends (55/45). Each wipe is laser-cut, laundered, and double-bagged under ISO-compliant conditions to minimize fiber shedding, ion release, and particle contamination.

Whether used for wafer cleaning, photolithography tools, or precision instruments, AAWipes’ wipes deliver dependable performance in critical environments.

2. Anti-Static and ESD-Safe Performance

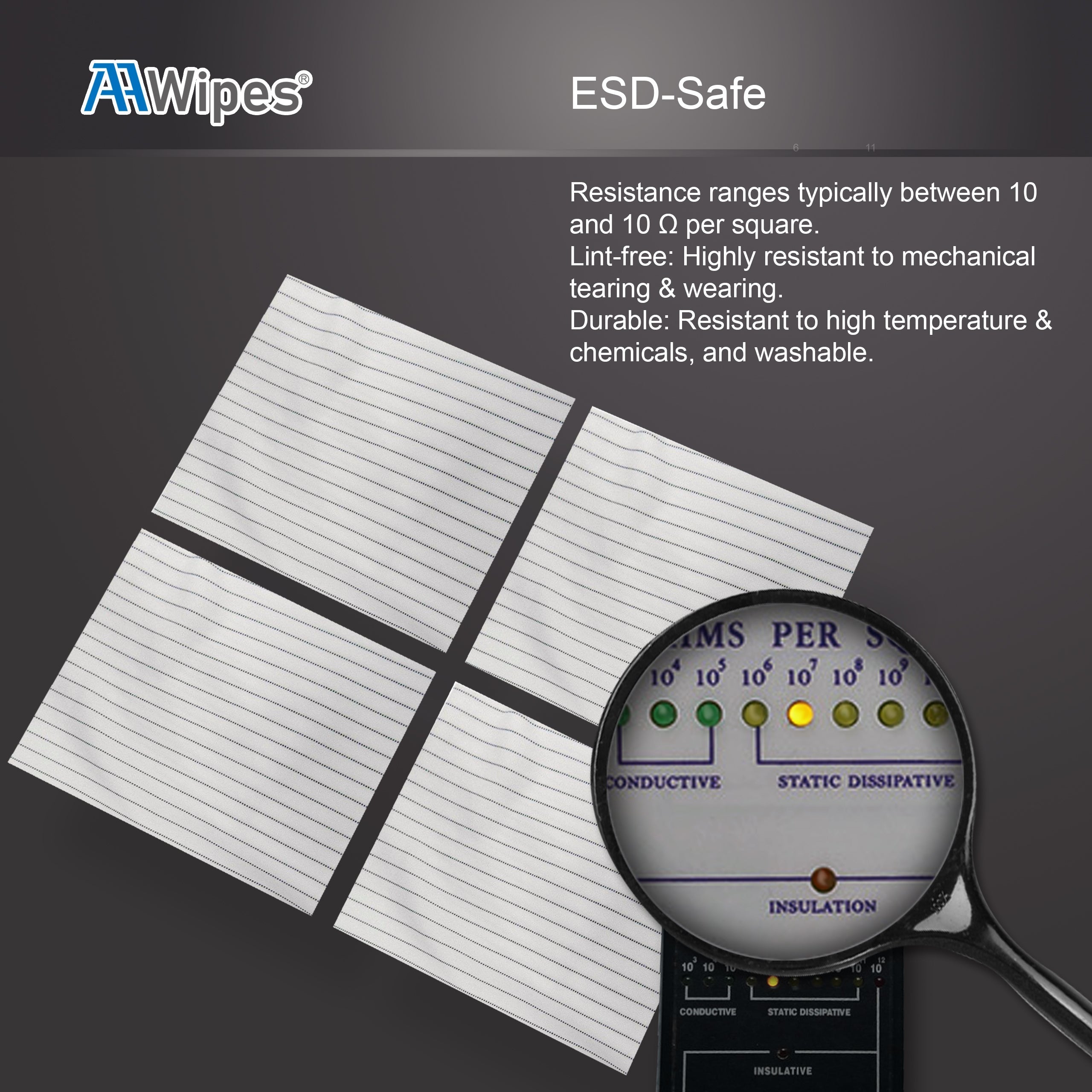

Electrostatic discharge (ESD) can destroy sensitive microchips and electronic components. To protect high-value assets, semiconductor facilities depend on anti-static wipes engineered to dissipate static safely during cleaning operations.

AAWipes provides anti-static wipes in bulk, manufactured with conductive yarns and advanced surfactant coatings that maintain static control without compromising absorbency or softness. These wipes are ideal for cleaning semiconductor tools, inspection stations, and packaging areas where static mitigation is essential.

3. Supplier Reliability and Bulk Scalability

In the semiconductor industry, downtime is costly — so reliability matters. AAWipes has built long-term partnerships with Fortune 500 companies, research institutions, and global technology leaders, supported by a 92% repeat purchase rate.

With established distribution networks across the United States, Canada, and Europe, AAWipes ensures fast and stable bulk delivery. Custom labeling, private branding, and OEM packaging are also available for distributors and enterprise buyers who require consistent supply and brand alignment.

Why Semiconductor Companies Trust AAWipes

- Certified Class 100–1000 cleanroom wipes for contamination-sensitive processes

- Anti-static and ESD-safe options in bulk packaging

- Consistent quality control and ISO-based production

- Flexible supply solutions for OEM, private label, or direct B2B orders

- Global logistics coverage with reliable bulk fulfillment

Final Thoughts

Selecting the right semiconductor wipes supplier goes beyond pricing — it’s about trust, precision, and performance. AAWipes helps semiconductor manufacturers maintain clean, controlled environments that protect product yield and process stability.

Explore the full AAWipes collection of cleanroom wipes, anti-static wipes, and precision cleaning solutions at AAWipes.com, or reach out to discuss your bulk order requirements today.