In industries like electronics manufacturing, optics, laboratories, and cleanrooms, even a tiny spark of static electricity can cause thousands of dollars in damage. Yet many end customers still treat wipes as “just another consumable.”

For industrial wholesalers and trading specialists in the U.S., Canada, and Europe, this creates both a challenge and an opportunity:

-

The challenge is helping customers understand why ESD-safe wipers are different from regular wipes.

-

The opportunity is positioning yourself as a trusted supplier who provides not only products, but also expertise and risk prevention.

Here’s a practical framework to communicate the value of ESD-safe wipers.

1. What Is ESD and Why Does It Matter?

Electrostatic Discharge (ESD) is the sudden release of static electricity between two objects with different charges. In everyday life, it feels like the “shock” you get from a doorknob in winter.

While harmless to people, ESD can silently destroy sensitive electronics. Studies show that voltages as low as 30 volts can damage semiconductors, sensors, and optical components—levels far below human detection.

-

Ordinary wipes generate static during cleaning, introducing risk instead of eliminating it.

-

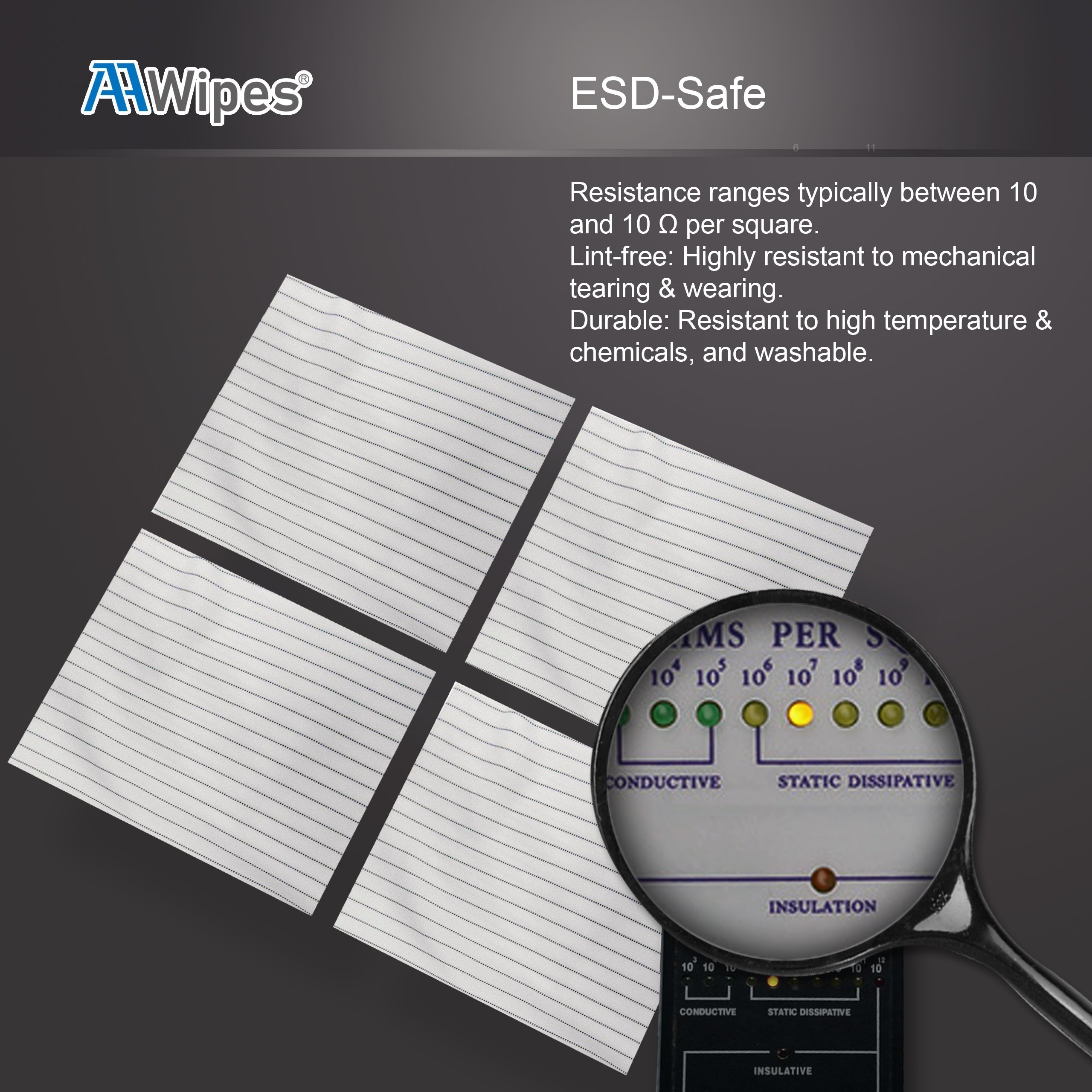

ESD-safe wipers are engineered with conductive fibers and antistatic treatments to dissipate static safely while removing dust, oil, and particles.

👉 Easy way to explain it: “Regular wipes may clean the surface but leave behind static charges. ESD-safe wipers clean without hidden risks.”

2. The Risks of Using Non-ESD Wipers

When customers hesitate, wholesalers should emphasize the real-world consequences of ignoring ESD protection:

-

Production failures: One invisible discharge can damage chips, boards, or precision optics.

-

Hidden costs: Failures caused by static often appear later, resulting in warranty claims and expensive recalls.

-

Compliance risks: Many North American and European customers now require ESD-safe consumables to pass audits.

-

Reputation loss: A single incident can cause clients to switch suppliers.

👉 Key message: “Saving a few cents on non-ESD wipes could cost thousands in rework, compliance issues, and lost contracts.”

3. Common Customer Objections and Sales Responses

Q1: What’s the real difference between regular wipes and ESD-safe wipes?

-

Answer: “Think of it like clothing—regular wipes are like wool sweaters that build static, while ESD-safe wipes are treated to release static safely.”

Q2: We’ve never had problems before. Why change now?

-

Answer: “Many companies only discover the issue after a costly failure or failed audit. With stricter ESD requirements in the U.S., Canada, and Europe, adopting ESD-safe products now prevents future setbacks.”

Q3: Aren’t ESD wipes more expensive?

-

Answer: “Yes, slightly. But they protect against failures worth far more than the price difference. For wholesalers, ESD-safe lines also mean higher-margin sales and stronger customer loyalty.”

Q4: How do I explain this to my customers?

-

Answer: “Position it as insurance. You’re not just selling wipes—you’re helping them reduce risk, comply with standards, and protect their reputation.”

4. Why ESD-Safe Wipers Are a Growth Opportunity for Distributors

For wholesalers and trading specialists, ESD-safe wipers are more than a consumable—they are a value-added product line that differentiates you from competitors.

-

Expand your catalog: Offer a professional solution for electronics, optics, and cleanrooms.

-

Meet customer demand: North American and European buyers increasingly require ESD-safe supplies.

-

Increase profitability: ESD-safe products often carry higher margins than general-purpose wipes.

-

Build authority: Providing technical knowledge strengthens your role as a trusted advisor, not just a supplier.

👉 Position yourself as the partner who delivers both products and expertise—that’s how you win long-term customers.

Frequently Asked Questions (FAQ)

Q: Are ESD-safe wipers required in all industries?

A: No, but they are essential in electronics, semiconductors, optics, and any environment where static-sensitive devices are used.

Q: How do ESD-safe wipers work?

A: They are made with conductive fibers or treated materials that dissipate static charges while wiping, preventing buildup.

Q: Can wholesalers market them to general cleaning customers?

A: Yes, though the strongest demand is in high-tech industries. Position them as a premium option for clients seeking compliance or reduced risk.

Q: Do ESD-safe wipers meet industry standards?

A: Quality products comply with international ESD standards (such as IEC 61340). This is critical for customers working with global supply chains.

Final Takeaway & Call to Action

For wholesalers and trading specialists in the U.S., Canada, and Europe, ESD-safe wipers are not just cleaning tools—they are risk management tools.

-

They protect sensitive electronics.

-

They help customers stay compliant with audits.

-

They reduce costly failures and build trust.

👉 Closing line for your customers: “ESD wipers aren’t an expense—they’re an investment in reliability, compliance, and customer trust.”

📩 Ready to add ESD-safe wipers to your product catalog?

Contact AAWipes today for bulk pricing, distributor discounts, and tailored supply programs for your market.